Establishing an oil extraction plant involves several critical stages, each requiring specialized machinery to ensure efficiency, quality, and safety. Below is a comprehensive breakdown of the essential components and their respective functions:

1. Seed Preparation

Before extraction, oilseeds must be properly prepared to maximize yield and quality.

- Cleaning Machines: Remove impurities such as dust, stones, and foreign materials from the seeds.

- Dehullers/Decorticators: Separate the hulls or shells from the kernels to enhance oil extraction efficiency.

- Crushers/Breakers: Reduce seed size to facilitate uniform cooking and efficient oil extraction.

3. Mechanical Oil Extraction

Mechanical extraction involves pressing the prepared seeds to extract oil.

- Oil Expellers/Screw Presses: Utilize mechanical pressure to extract oil from seeds.

4. Solvent Extraction

For seeds with low oil content or to extract residual oil from pressed cakes, solvent extraction is employed.

- Solvent Extractors: Use solvents like hexane to dissolve and extract oil from oilseed cakes.

5. Desolventizing and Toasting

After solvent extraction, the meal contains residual solvent that must be removed.

- Desolventizer-Toasters: Heat the meal to evaporate residual solvent and toast it to improve nutritional value.

6. Oil Refining

Crude extracted oil often requires refining to improve its quality and suitability for consumption.

- Neutralizers: Remove free fatty acids by neutralization with alkali solutions.

- Bleachers: Eliminate pigments and impurities using bleaching earth or activated carbon.

- Deodorizers: Remove volatile compounds that cause undesirable odors and flavors through steam distillation.

7. Filtration

To ensure clarity and purity, the oil is filtered to remove suspended particles.

- Filter Presses: Separate solids from the oil using pressure filtration.

8.Labeling Machines

Apply labels accurately to provide product information and branding.

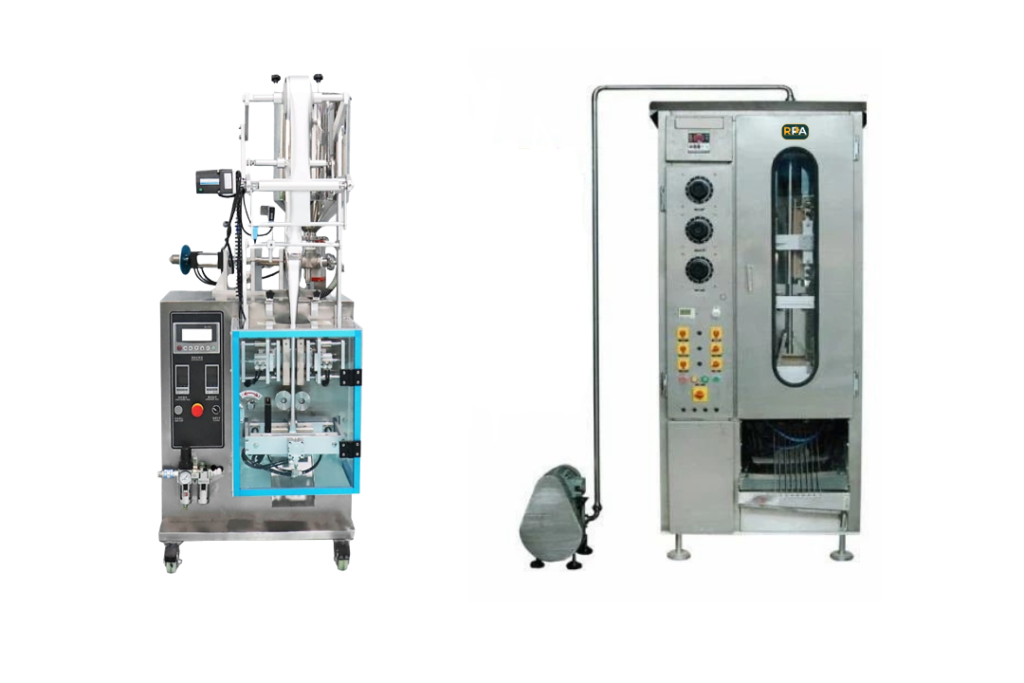

8. Automatic Pouch Packaging

The refined oil is then packaged for distribution and sale.

Automatic Filling and Packaging Machines:

Ensure accurate filling and hygienic packaging of the final product.