RPA Manufacturing and Trading Company specializes in the manufacturing and installation of Rice Mill Plants, ensuring high efficiency, durability, and premium quality rice production. Below is a detailed breakdown of the key components of our Rice Mill Plant:

1. Elevator

The Double Elevator is responsible for lifting and transporting rice grains between different processing stages. It ensures efficient material handling, reducing manual labor and improving workflow automation.

2. Paddy Separator

The Paddy Separator efficiently separates brown rice from paddy using density differences. This is a crucial step in ensuring that only dehusked rice moves forward in the processing line.

3. Rice Whitener

The Rice Whitener polishes the surface of brown rice, removing the outer layers to produce clean, white rice. This machine ensures uniformity in texture and improves the rice’s appearance for market standards.

4. Broken Rice Sifter

The Broken Rice Sifter sorts whole rice grains from broken ones using sieves and vibration technology. It helps in maintaining the quality of the final product by separating different grades of rice.

5. Switch Panel

The Switch Panel houses the control system for the entire rice mill plant. It allows operators to monitor and control different machines for optimal performance, efficiency, and safety.

6. Circuit Assembly

The Circuit Assembly is the electrical control unit that ensures smooth operation of all connected machinery. It provides power regulation, automation, and troubleshooting for the plant’s functioning.

7. Huller

The Huller removes the outer husk from the paddy, converting it into brown rice. This process is essential before rice undergoes further polishing and refining stages.

9. Destoner

The Destoner effectively removes stones, dirt, and heavy impurities from the rice. It ensures that only clean grains enter the milling process, maintaining food-grade quality standards.

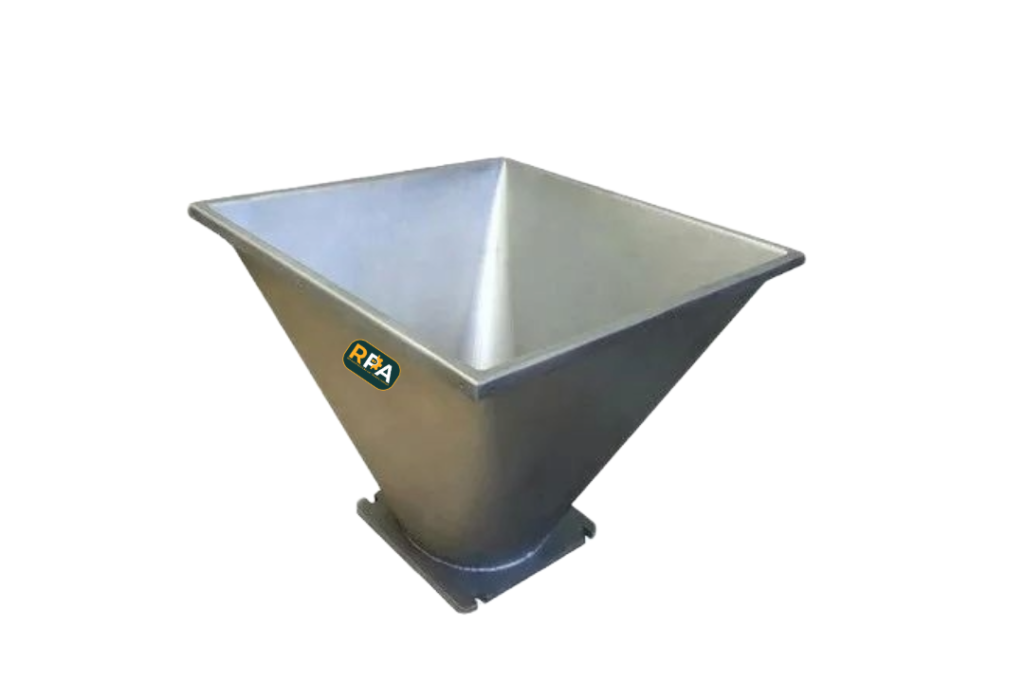

10. Feed Hopper

The Feed Hopper is the entry point where raw paddy is loaded into the plant. It controls the flow of rice into the processing units, preventing overflow and ensuring smooth operation.

11. Checking Window

The Checking Window allows operators to inspect and monitor the rice milling process in real-time. This helps in detecting any malfunctions or quality issues early in the production cycle.

Conclusion

Our Rice Mill Plant is designed with advanced machinery to ensure smooth, efficient, and high-quality rice processing. Whether for small-scale or large-scale production, our solutions meet industry standards and customer requirements. Contact RPA Manufacturing and Trading Company today for more details on setting up your Rice Mill Plant!

- All

- Rice Mill Plant