Establishing a spice processing plant with automated packing and filling capabilities involves several critical stages, each requiring specialized machinery to ensure efficiency, quality, and hygiene. Below is a comprehensive breakdown of the essential components and their respective functions:

1. Raw Material Cleaning

Before processing, raw spices must be thoroughly cleaned to remove impurities such as dust, stones, and foreign materials.

- Cleaning Machines: Utilized to eliminate unwanted particles, ensuring that only pure spices proceed to the next stage.

2. Drying

Post-cleaning, spices often require drying to achieve the desired moisture content, which is crucial for grinding efficiency and product shelf life.

- Dryers: Employed to reduce moisture content, preventing mold growth and preserving flavor.

3. Grinding

The dried spices are then ground into powder form.

- Pulverizer Grinding Machines: These machines grind spices into fine powders, ensuring uniform particle size.

4. Sieving

To ensure uniformity and remove any larger, unground particles.

- Vibro Screening Machines: Used to achieve uniform particle sizes and remove oversized materials.

5. Blending

For spice mixes, different ground spices are blended to achieve the desired flavor profile.

- Ribbon Blender Mixers: Ensure homogeneous mixing of various spice powders.

6.Rosting Machines

Roasting enhances the flavor, aroma, and shelf life of spices by reducing moisture content and decreasing bacterial growth.

- Spice Roasting Machines: These machines are designed to roast various spices such as coriander, fenugreek seeds, fennel, bay leaves, cumin, and sesame. They operate using indirect heating methods, which minimize aroma loss and ensure uniform roasting. For instance, Rieco’s Spice Roasters utilize an indirect heating method, minimizing aroma loss while handling a variety of individual or mixed spice products.

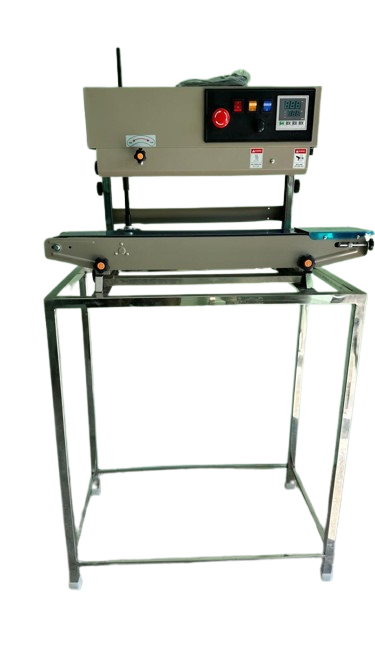

7. Packaging

The final product is packed into appropriate packaging to maintain freshness and facilitate distribution.

- Automatic Packing and Filling Machines: These machines automate the packaging process, ensuring accuracy and hygiene.

By integrating these components, a spice processing plant can achieve efficient production with high standards of quality and hygiene.