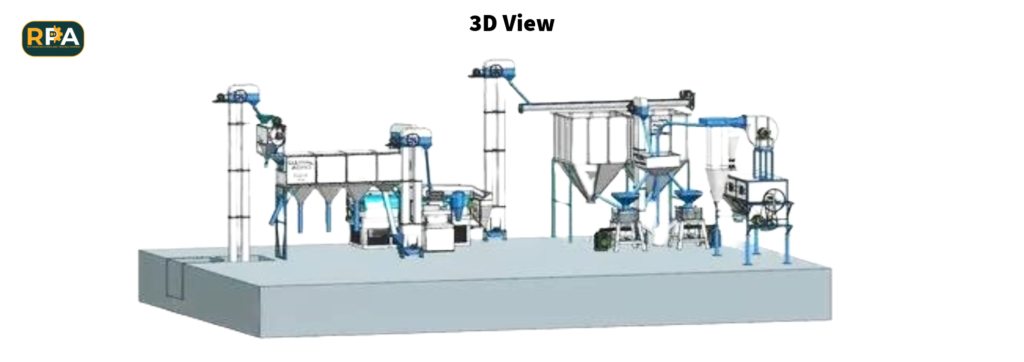

RPA Manufacturing and Trading Company specializes in the manufacturing and installation of Atta Chakki Machines, offering a complete solution for wheat processing. Our advanced machinery ensures efficiency, durability, and high-quality flour production. Below is a detailed breakdown of the key components of our Atta Chakki Plant:

Jahrana / Wheat Cleaning Machine

The Jahrana (Wheat Cleaning Machine) is designed to remove dust, dirt, stones, and other impurities from raw wheat. This ensures that the wheat used for flour production is clean and free from contaminants, enhancing the quality of the final product.

De-Stoner with Dust Fan

The De-Stoner effectively separates stones and heavy impurities from wheat using air suction and vibration technology. The dust fan removes fine dust particles, ensuring a clean wheat input into the milling process.

Reel Machine

The Reel Machine is used for grading and sorting wheat based on size. It ensures uniformity in wheat grains, which is essential for consistent flour quality.

Roller Machine

The Roller Machine is the core milling unit where wheat is ground into fine flour. It consists of high-quality rollers that crush and refine the wheat grains while maintaining nutritional value and texture.

Elevator

The Elevator is a grain-handling system that lifts wheat from one processing unit to another with minimal spillage and breakage, ensuring a smooth flow in the production line.

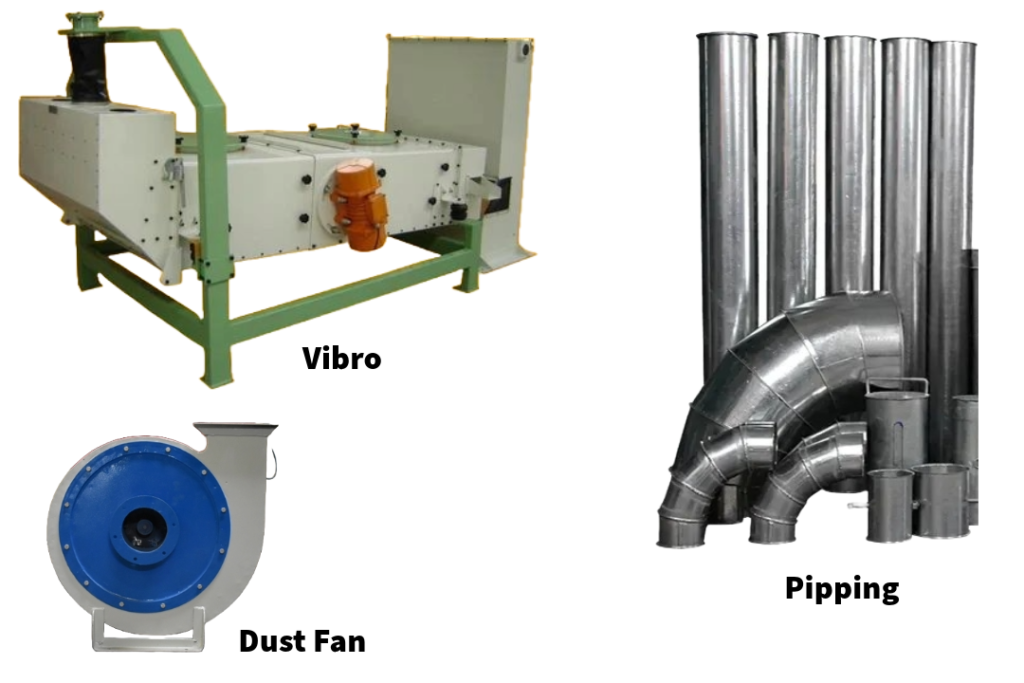

Vibro with Dust Fan

The Vibro Machine is a vibrating separator that removes fine impurities from wheat before milling. The integrated dust fan ensures a dust-free environment, enhancing hygiene and efficiency.

Tank

The Storage Tank is designed to hold processed wheat or flour temporarily before further processing or packaging. It is made of high-quality, food-grade material to ensure safety and hygiene.

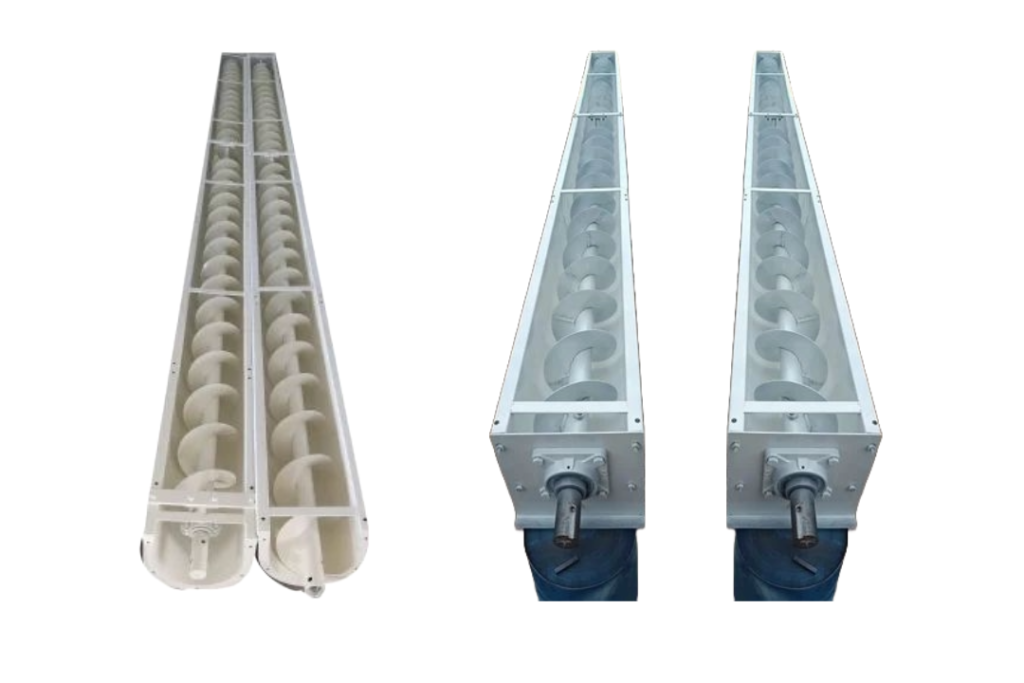

Screw Conveyor / Brum

The Screw Conveyor (Brum) is used to transport wheat and flour efficiently within the processing units. It ensures a smooth and controlled material flow, minimizing wastage and maintaining consistency in production.

Store Bin (Small)

The Store Bin is a compact storage solution used for holding smaller batches of wheat or flour during different stages of processing. It ensures a continuous workflow without interruptions.

Chakki with Stone

The Chakki with Stone is a traditional grinding unit that grinds wheat using a natural stone mechanism. It retains essential nutrients, ensuring high-quality and nutritious flour production.

High Pressure with Cyclone, Air Lock, and Confection

This system ensures effective air management within the plant. The High Pressure Cyclone removes fine particles from the milling process, the Air Lock prevents air leakage, and the Confection System maintains an optimal processing environment.

Centrifugal / Plant Shifter

The Centrifugal Shifter or Plant Shifter is responsible for separating different grades of flour and byproducts. It ensures uniformity in flour texture and quality by sifting out coarse particles.

Auto Weight Machine and Automatic Packing System

The Auto Weight Machine ensures precise measurement of flour before packaging. The Automatic Packing System efficiently packs flour into various sizes, reducing manual labor and ensuring hygiene.

Conclusion

Our Atta Chakki Plant is designed with advanced machinery to provide seamless flour processing, ensuring high-quality output. Whether for small-scale or large-scale production, our solutions meet industry standards and customer needs. Contact RPA Manufacturing and Trading Company today for more details on setting up your Atta Chakki Plant!

Price According to your Customization: 30,00000~1.5 Cr

- All

- Atta Chakki Plant